Thorough examination of each storage tank component is imperative. Neglecting NDT inspections poses a risk of revenue loss and heightened chances of expensive accidents. Leveraging pioneering inspection technologies enhances oil spills prevention and preparedness as well as other potential asset issues. These advanced inspections provide precise estimates for the next inspection interval and the remaining lifespan of the asset. Although assessing tank components can be challenging, recent advancements enable more efficient and expedited inspections, facilitating swift decision-making for a prompt return to service.

Inspecting Tank Floors For Corrosion

The most common technology used to inspect bottom plates for corrosion and pitting is magnetic flux leakage (MFL) given its efficiency (up to 1m/s or 3ft/s) with a high probability of detection (PoD). MFL uses strong permanent magnets to induce a magnetic field in the floor plate. When it encounters corrosion, the magnetic field leaks and is detected by the high-resolution sensor array. The Floormap®X combines MFL with the unique technology, surface topology air-gap reluctance sensors (STARS). This combination enables complete mapping of storage tank floors with the ability to discriminate between top- and bottom-side defects. Our complete solution results in more value to the maintenance and repair plan created when defects are found. More detailed information on the FloormapX is available in this blog.

The FloormapX with its onboard data acquisition software, SIMS GO, has been developed to efficiently incorporate data from complementary prove-up technologies such as ultrasonic testing (UT) for added confidence and a more comprehensive report. Spot UT thickness readings are still widely employed for determining true remaining wall thickness values while phased array technology offers high-resolution information on the corrosion type and shape. This type of inspection can be performed quickly using a semi-automated XY scanner.

Inspection Data Management Software

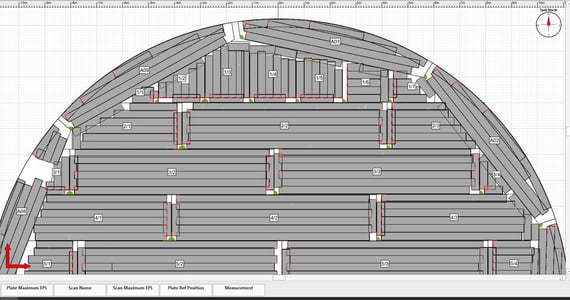

A single tank floor inspection can contain numerous individual floor plates. An inspection data management and reporting software like SIMS PRO can automatically stitch all the data into a single, holistic view. With SIMS PRO, defects can be easily located with accurate X and Y coordinates classified in terms of surface origin and relevance. This vastly reduces the likelihood of human error in the inspection and reporting process.

Managing many datasets is demanding and time-consuming; luckily, SIMS PRO does this all for you! Numerous advantages include intuitive navigation, a fully automated and classified indication list, and the ability to generate EEMUA and API compliant reports. SIMS PRO enables recording datasets at previously classed dead zone areas, specifically within 12 millimeters (0.5 inches) of the tank shell to floor weld, commonly referred to as the critical zone. This increases the overall inspection coverage and reduces the need for secondary, time-consuming inspection methods. More information can be found here.

Assessing Bottom Plate Welded Joints For Cracks

Bottom plate welded joints are prone to cracking and for this specific application, the most widespread inspection method is alternating field current measurement or ACFM®. Compared to magnetic particle inspection (MPI), ACFM is faster and more reliable which explains why the technology is so prevalent for plate weld inspection. Eddyfi Technologies’ ACFM array probe makes for an even more productive inspection. It features a 90-millimeter (3.5-inch) coverage and detection of both axial and transverse cracks simultaneously. Its 16 spring-loaded shoes make it possible to conform to protruding weld caps up to 12 millimeters (0.5 inches) high. The ACFM array probe can also size cracks 20 millimeters (0.8 inches) deep and tolerates up to 10 millimeters (0.4 inches) of coating.

Tangential eddy current array or TECA™ is another viable technology for performing this inspection, particularly with the utilization of Sharck™ probes. They are specifically engineered to detect and size cracks in carbon steel welds. The probe, featuring 22 high-resolution elements, effectively addresses permeability variations and has a liftoff compensation tool designed for coatings up to 3 millimeters (0.1 inches) thick.

In summary, both ACFM and TECA Sharck probes can detect axial and transverse surface-breaking cracks without the need to remove paint or protective coatings. They can measure the length as well as the depth of cracks. Both options are available in either a single-element pencil probe or an array equipped with spring-loaded sensors to cover the entire width of the tank floor weld.

Inspecting Tank Annular Rings For Corrosion

When the installation configuration allows, in-service inspection of the annular ring is possible with Eddyfi Technologies’ pulsed eddy current (PEC) tank floor probe. This specially designed probe screens and assesses corrosion within the annular ring—an identified target area that may be exposed either due to tank floor sagging or through light excavation of the surrounding soil.

The probe is equipped with a slender 4.8-millimeter (0.2-inch) titanium blade capable of sliding up to 400 millimeters (16 inches) beneath aboveground storage tank annular rings. This feature facilitates the assessment of the remaining wall thickness of this crucial component, susceptible to corrosion. The probe sensor exhibits a tolerance of up to 13 millimeters (0.5 inches) of liftoff. Supported by Lyft® software, the system incorporates an optimization algorithm for thickness measurements, ensuring optimal performance and repeatability. Refer to the details provided in this application note.

Detecting Cracks In Tank Annular Ring Welded Joints

Similar to tank floor welded joints, this is another area where ACFM is the most common inspection method. Eddyfi Technologies offers an ACFM fillet weld array probe specifically designed for the inspection of such components. This probe is shaped to conform to the weld profile and uses an array of sensors to inspect the weld cap, toes, and heat affected zones or HAZ in a single pass. The ACFM probe also features 3BZ sizing technology which enables accurate length and depth measurements of cracks without the need for an encoder nor surface markings. More information can be found in this article.

Corrosion Mapping Tank Shells

One Beyond Current method used to assess tank shell wall thickness is with a remote-access UT crawler. Designed to perform cost-effective thickness measurements on aboveground ferromagnetic structures without the need for scaffolding or rope access, the Scorpion 2 is Eddyfi Technologies’ ultrasonic testing tank shell inspection crawler. It performs line scans on the tank shell surface and has proven itself as a reliable inspection system for overall detection of corrosion. This screening tool replaces random spot checks at cardinal points which has a lower PoD.

Once an area has been identified with corrosion, localized phased array ultrasonic testing (PAUT) can be performed for accurate corrosion mapping. Eddyfi Technologies offers an automated PAUT inspection solution tailored to answer industry needs. The technology is 10 times faster than conventional UT and its resolution is easily adjusted from 0.5 to 50 millimeters (0.02 to 2 inches) depending on the required scan speed and detection resolution. More information for this efficient UT corrosion mapping tool can be found in this blog.

Reviewing Tank Shell Plate Welded Joints For Cracking

Scorpion 2 can be used as an efficient screening method to identify cracks in shell plate welds. A cross-check can be made to get a more in-depth analysis of a specific area with the NDT scanner for phased array UT as it is designed to be effortlessly deployed in a rope access inspection.

Furthermore, ACFM as well as TECA technologies have also proven successful in detecting and sizing cracks in storage tank shell joint welds. Both solutions can provide information about the length as well as the depth of the crack. They can be either used manually by a rope-access technician or via mounting the sensor on a robot such as the VersaTrax™ inspection crawler.

Measuring Corrosion In Tank Roofs

While the tank is still in service, Scorpion 2 can be used to detect corrosion in a grid pattern on roof plates. Again, this crawler serves mainly as a preliminary tool to ensure if it safe for operators to follow up with the inspection using the FloormapX.

Cases of floating roofs, insulation with weatherproof materials, or the application of anti-slip paint coatings can make UT or MFL measurements unusable. In these scenarios, PEC can be utilized as a reliable and accurate tool to screen for corrosion and has been proven effective in a field test as described in this blog. After screening for corrosion with PEC, areas of interest where corrosion is detected can be stripped of their coating or weatherproofing material to allow for UT or MFL inspection.

Inspecting Tank Piping Systems For Corrosion

When confronting challenges posed by inaccessible piping and generalized corrosion damage mechanisms, Eddyfi Technologies Sonyks™ emerges as the recommended screening tool. Distinguished by innovative guided wave testing (GWT) technology that incorporates both long-range ultrasonic testing (LRUT) and medium-range ultrasonic testing (MRUT) systems, Sonyks stands out for its efficiency in acquiring data. The system's prowess lies in its ability to cover long inspection distances and finesse when navigating through shorter pipelines, utilizing its medium-range capabilities ensuring a comprehensive inspection process. This combination of extended diagnostic length and enhanced sensitivity and resolution positions Sonyks as a reliable solution for addressing diverse inspection needs, from long-distance pipelines to those with more confined spaces and smaller defects. For a deeper dive into its capabilities, explore the detailed information available on this guided wave testing blog.

Further inspection for corrosion and pitting can be performed using our dedicated MFL inspection tool: Pipescan™ HD. Featuring a high-resolution scan, Pipescan HD can detect internal and external corrosion pitting with very high PoD and inspection speeds of up to 1 meter or 3 feet per second.

Indications detected by Pipescan HD can then be further inspected and proved up with a high-resolution phased array UT scan using this advanced modular ultrasonic scanner. This combination of technologies ensures very high productivity coupled with accurate remaining wall thickness measurements.

For insulated pipes, PEC makes it possible to screen for corrosion without stripping assets from their insulation and weather jackets. To further improve productivity, Eddyfi Technologies introduced the first PEC system on the market with support for simultaneous pulsed eddy current array (PECA) acquisition. More information on this solution and its benefit can be found on this blog.

The Total Tank Inspection Takeaway

The majority of aboveground atmospheric storage tank components can be reliably inspected through a wise combination of ACFM, GWT, MFL, PEC, TECA and UT for maximum efficiency, minimum down time, and optimal asset management strategies. Hardware like Amigo2, FloormapX, Lyft, Pipescan HD, Reddy, Scorpion 2, Sharck, Sonyks, and VersaTrax—as well as software like SIMS PRO—can easily help you reach this very important goal.

Ready to take the next step? Explore the Eddyfi eStore for instant pricing to our complete product portfolio and your one-stop PAUT shop, brush up your knowledge at the Eddyfi Academy, and get in touch with our team of friendly experts ready to discuss your next tank inspection campaign.

.jpg?width=570&height=378&name=NAVIC-Tank2%20(2).jpg)